60 To 2500mesh Powder Fineness Uniform Powder Making Porang Grinder

Product introduction:porang grinder

BSP porang grinder (air classifier) is a pulverizer that can produce very fine

powder. It is used for crushing sugar, and the output can reach 60

~ 1000 mesh. Used for grinding dried ginger and turmeric. This type

can also be ground into very fine powder. Moreover, the pulverizer

can produce very uniform powder, and the distribution of powder is

also very uniform.

Technical data:porang grinder

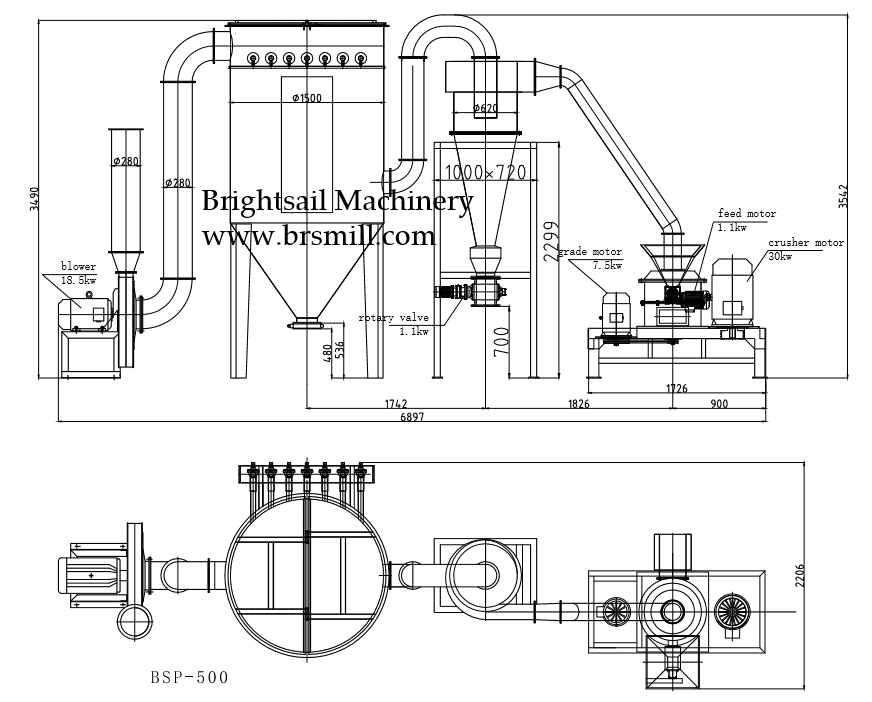

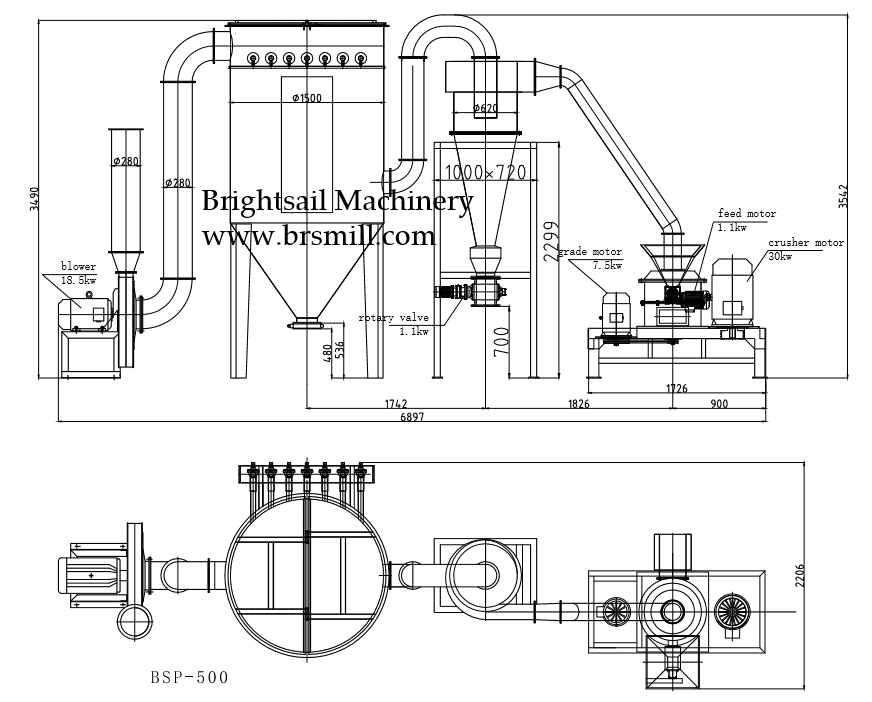

| Model | BSP-350 | BSP-450 | BSP-500 | BSP-750 |

| Input size(mm) | <15 | <15 | <15 | <15 |

| Fineness(mesh) | 60-2500 | 60-2500 | 60-2500 | 60-2500 |

| Capacity(kg/h) | 20-200 | 40-500 | 60-800 | 120-1800 |

| Crush motor(kw) | 11 | 18.5 | 30 | 55 |

| Grade motot(kw) | 1.5 | 4 | 5.5 | 11 |

| Blower(kw) | 7.5 | 11 | 18.5 | 37 |

| Feed motor(kw) | 0.55 | 0.55 | 0.75 | 1.5 |

| Discharge motor(kw) | 0.75 | 0.75 | 1.1 | 1.5 |

| Speed of principle axia(rpm) | -6500 | -5350 | -4600 | -3100 |

| Grading impeller speed(rpm) | 4000 | 4000 | 3500 | 3000 |

| Weight(kg) | 1600 | 1800 | 2300 | 3100 |

Working method:porang grinder

The material is fed through a screw conveyor into a grinding

chamber, where it is cut and ground by rapidly rotating blades. The

powder passes through the guide ring into the classification

chamber. As the classifier wheel rotates, air and Centrifugal

Forces Act simultaneously on the powder. The particles with size

larger than the critical diameter (graded size) have larger mass

and are thrown back to the grinding chamber to be broken again.

Particles smaller than the critical diameter enter the cyclone

separator and the dust collector.

Advantages:porang grinder

1. Compact design and reasonable structure. There is a grading

mechanism inside the material, which can carry out grinding and

grading at the same time to reduce energy consumption.

2. This machine is equipped with a fan for continuous heat

dissipation, which is suitable for grinding heat-sensitive

materials.

3. Strong adaptability and narrow particle size distribution. The

particle size of the product is uniform, and the fineness can reach

80-320 mesh.

4. In the case of non-stop, the uniform distribution of product

particle size can be achieved by adjusting the speed or air

classifier.

5. The upper cover of the main unit is opened by a pneumatic

spring. The main structure can be opened in both directions to

facilitate the cleaning and maintenance of internal components.

6. The main abrasive parts are made of high-grade alloy tool steel,

which greatly prolongs the service life or replacement cycle of the

worn parts.

7. The bearing system adopts imported high-speed precision

bearings, running smoothly, with low vibration and noise.

8. The pipeline has a quick disassembly structure, which is easy to

disassemble and clean.

9. Equipped with cyclone separator and dust collector, there is no

dust in the production process. The dust bag can effectively

collect the fine powder in the airflow, thereby meeting the clean

and environmental protection requirements of exhaust gas emission.

10. The fine powder collected in the bag can be effectively

recycled. Reduce material wear.

Detailed images:porang grinder

Contact us,we can give you the most appropriate advice

our email: info@brightsail-asia.com

website:www.brsmill.com

Whatsapp: +8615961653782